PylonAI Precast Solution

Let's Witness How Our Product Transforms Every Stage of the Precast Lifecycle – From Design and Fabrication to Inspection, Delivery, Installation, and Invoicing.

Design

Automatic extraction and retrieval: Extraction and retrieval of precast component list from precast framing plan and panel specifications from panel drawings made effortlessly.

Digital Updates: Automatically update the precast list in real-time for design changes or revisions.

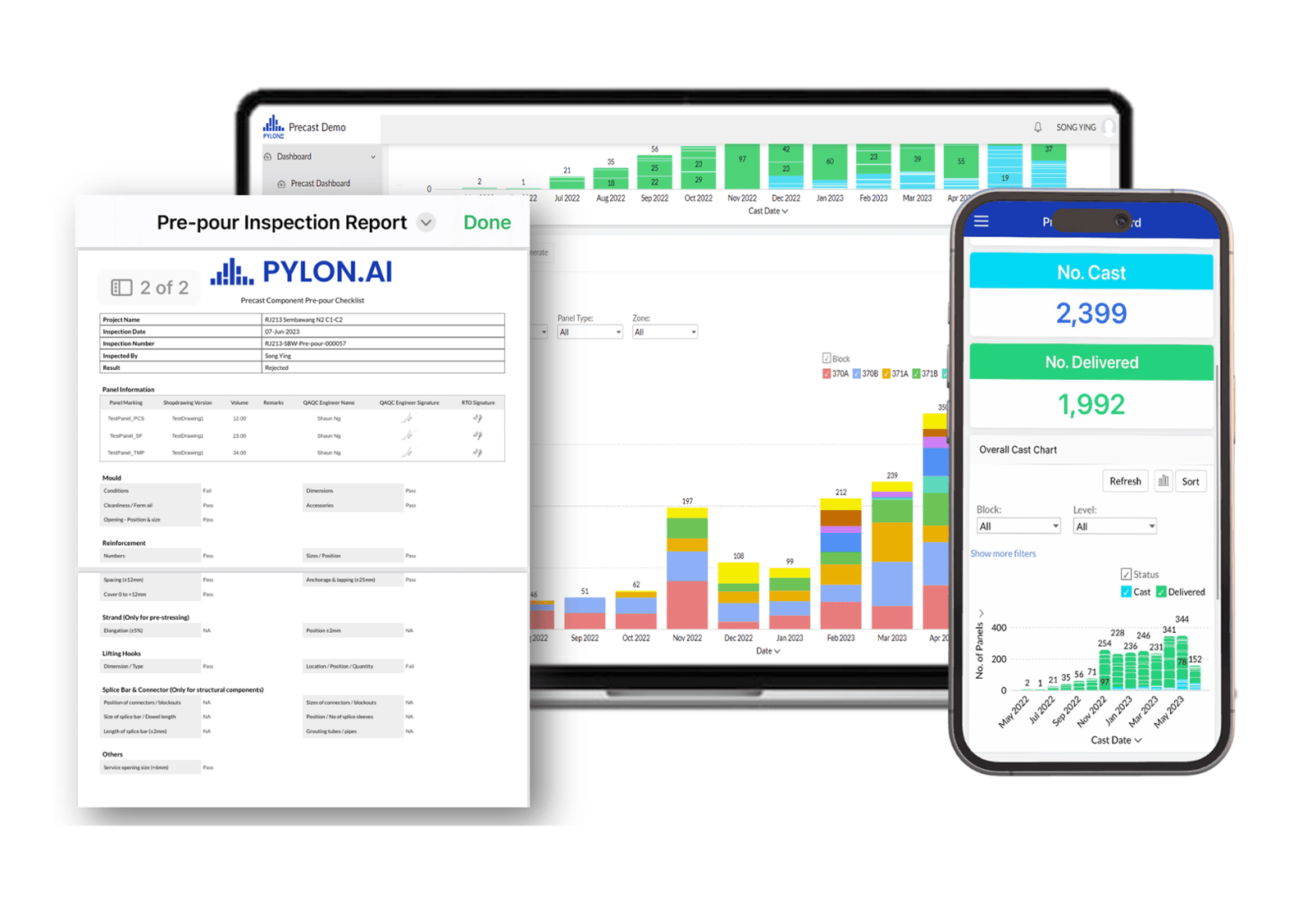

Fabrication

Real-time tracking: Digitally displaying component locations in real-time for seamless tracking through IoT devices.

Digital Precast Casting Schedule: With digital tracking, the process of recording and managing casting details becomes efficient and accurate, ensuring effective schedule management and reducing errors.

Inspection

Digital Inspection Records: Inspection findings are recorded digitally, eliminating paper forms and manual data entry.

Efficient Real-time Sharing: Inspection results are instantly and efficiently shared electronically with stakeholders, reducing administrative tasks and improving accuracy.

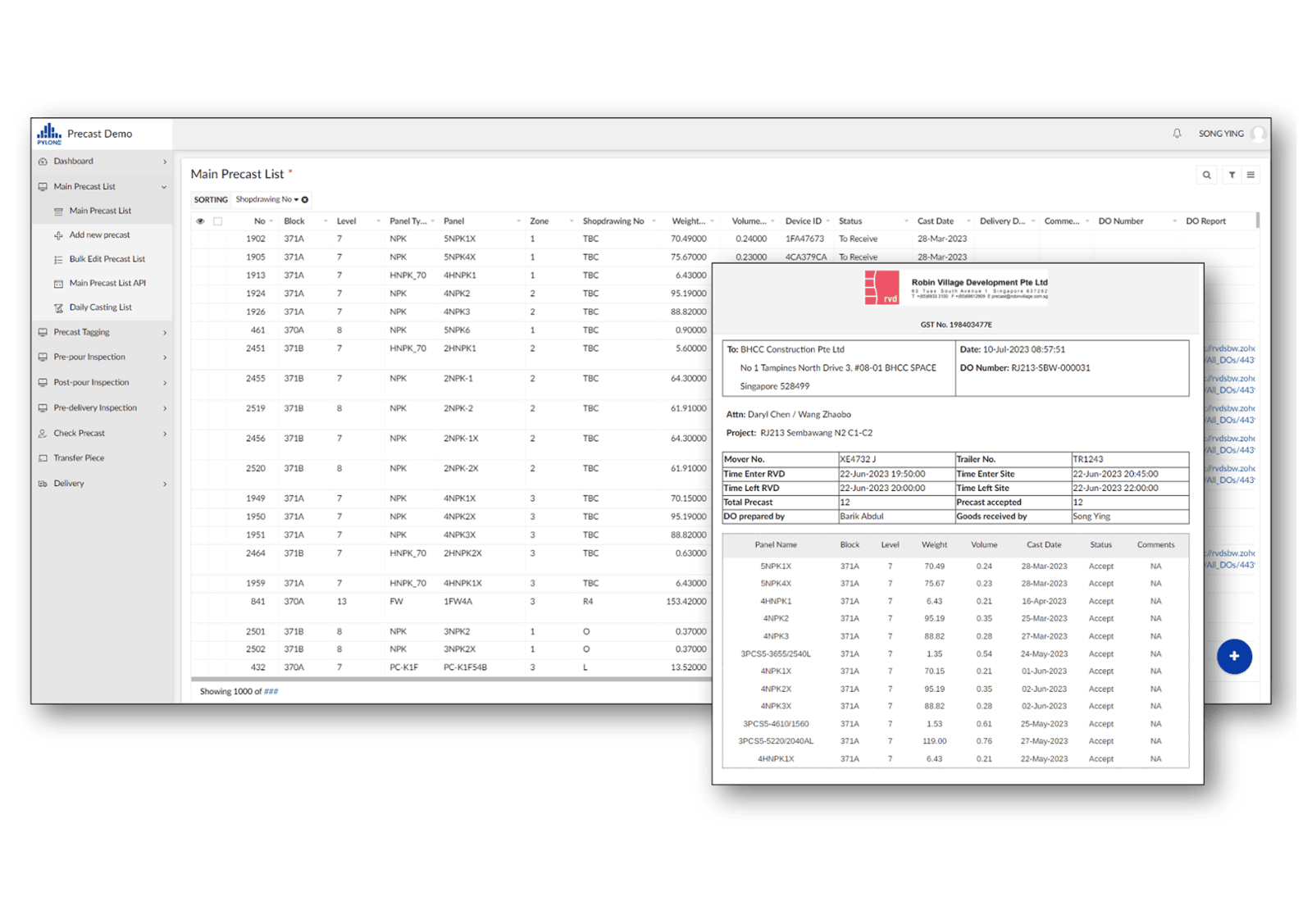

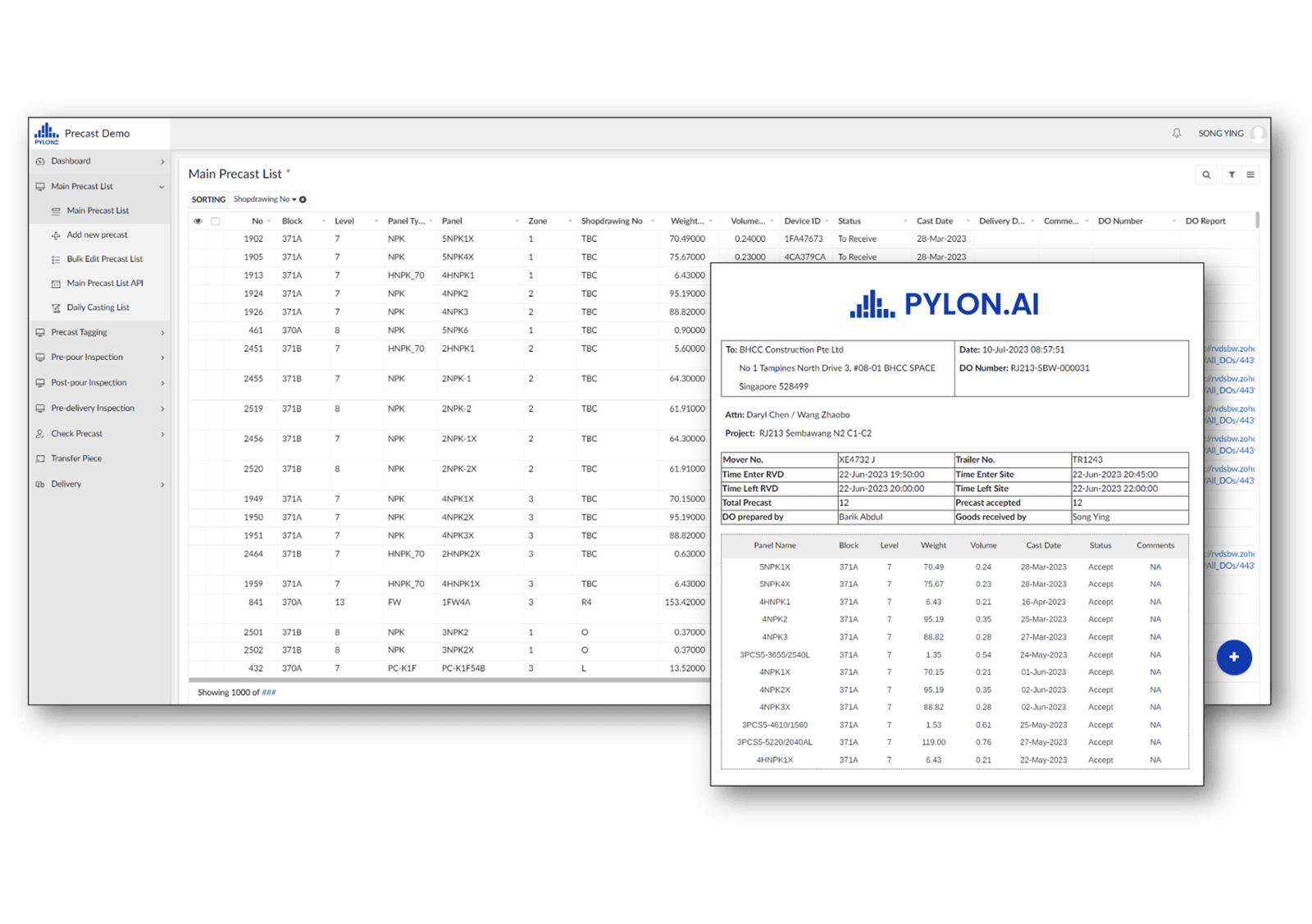

Delivery

Digital Documentation: Automating the generation of delivery orders and storing them in a consolidated precast list streamlines processes, making consolidation and locating specific delivery information simpler.

Automated Precast List Updates: Systems update the precast list with real-time delivery information, reducing manual work and ensuring accuracy.

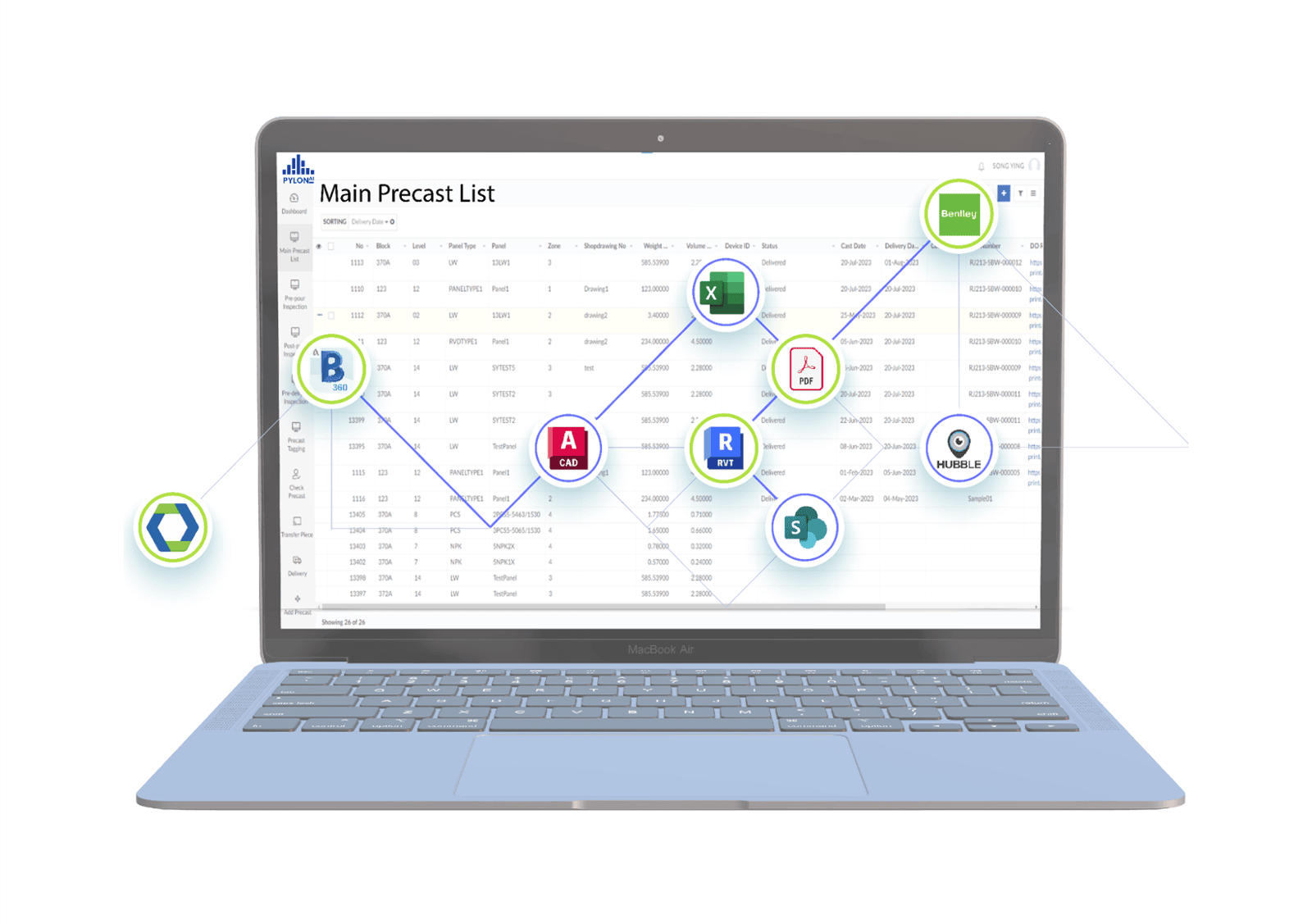

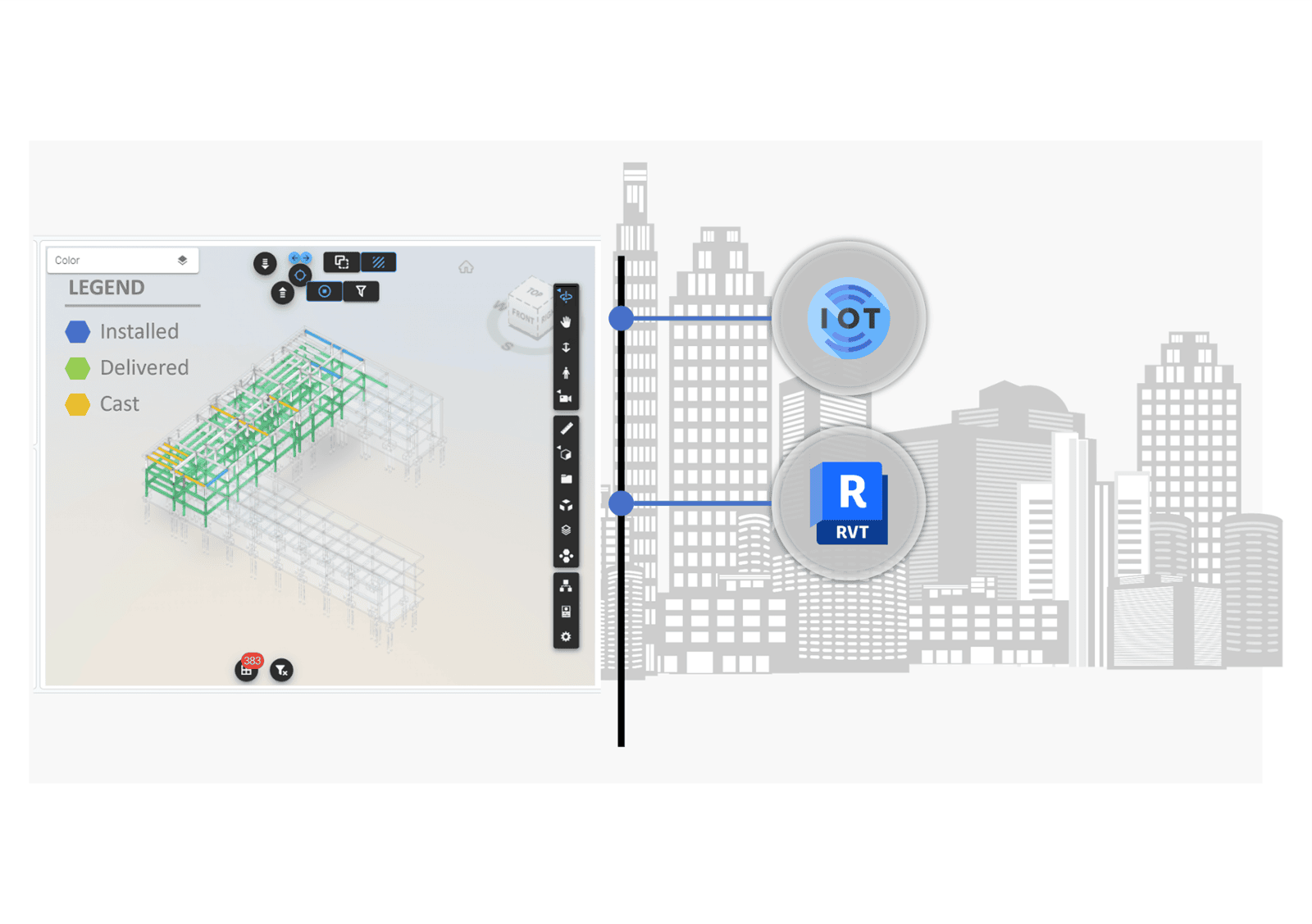

Installation

Digital installation workflow: Efficient and streamlined workflow for precast installation using digital technologies.

BIM-IoT integration: Integration of Building Information Modelling (BIM) and IoT for real-time panel status updates, enhancing coordination and data analysis.

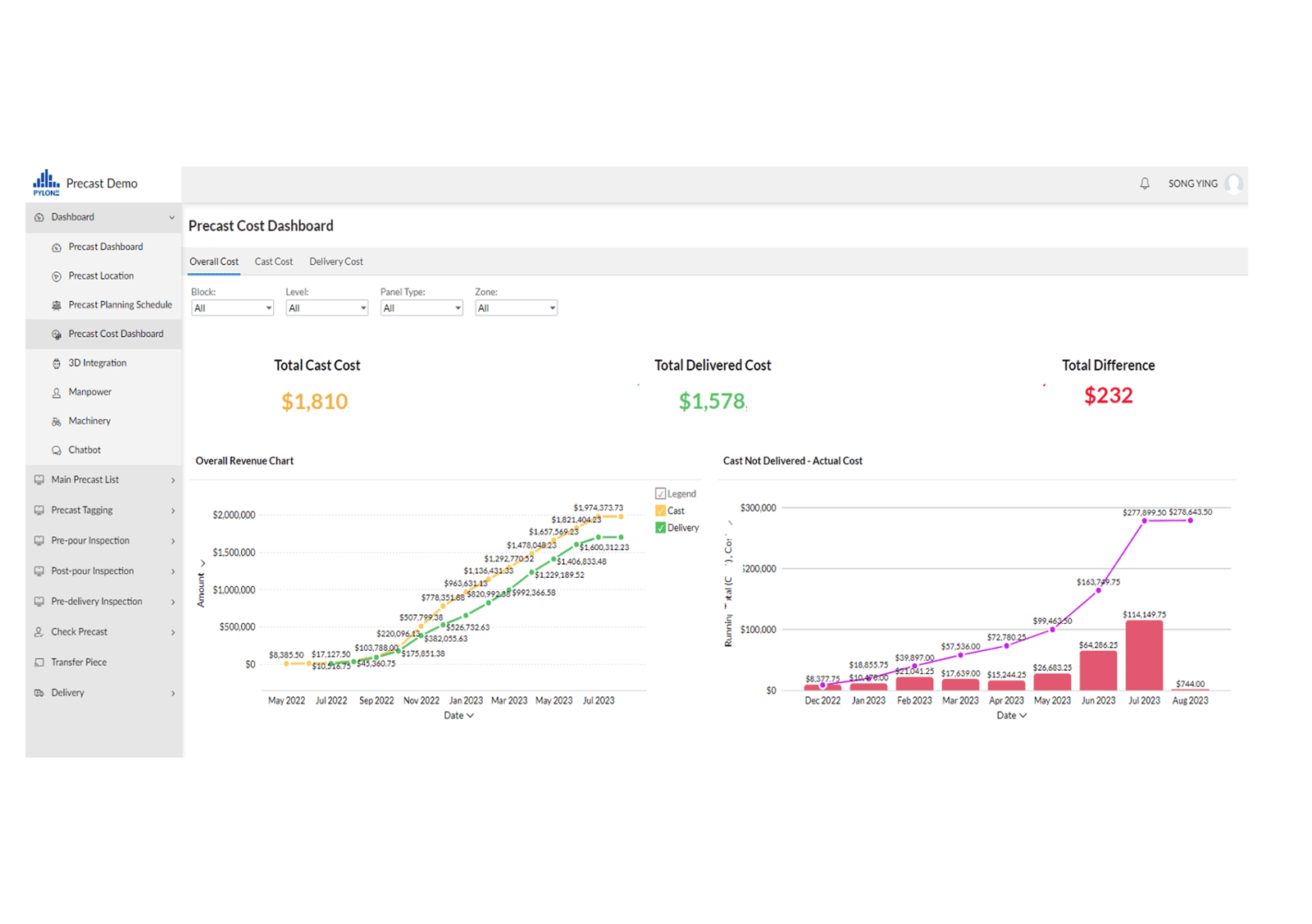

Claims

Automated Invoice Matching: Consolidated database and auto-generated invoices eliminate the need for manual matching, streamlining the invoice verification process.

Streamlined Work Verification: Efficiently verifies work done through digital claims, avoiding delays and disputes.

Improved Delivery Order Management: Enables easy tracking and management of digital delivery orders, ensuring accuracy and certainty in the invoicing process.

Concerned About Costs? Don't Worry – Discover the Grant Available!

Concerned About Costs? Don't Worry – Discover the Grant Available!

PIP for DfMA manufacturing facilities

Customers could enjoy up to S$300,000 grant for their DfMA manufacturing facilities such as precast concrete production and fit out facilities for PPVC, prefab MEP and PBU when adopting our digital solution.